|

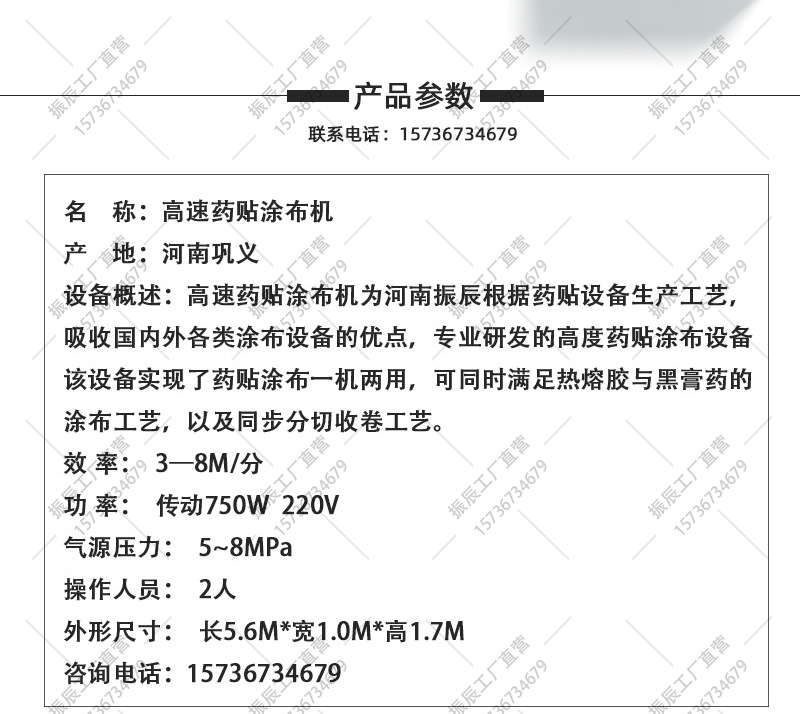

| ¥46800价格 | 可定制型号 | 振辰品牌 | 台单位 |

涂布机工作原理

1、工艺要求 1. Process requirements 涂布机 Coating machine 涂布机需要将胶或者油墨类物质均匀粘连在铝箔、塑料薄膜或者布料纺织品表面,对涂布工艺要求比较高,不仅要求涂布高度均匀而且要能够实现高速不停机换卷以提高生产效率。 Coating machine needs to be plastic or material uniform ink adhesion on surface of aluminum foil and plastic film or textile cloth, the coating technology demand is higher, not only requires highly uniform coated and must be able to achieve high-speed non-stop change volume in order to improve production efficiency. 2、方案优点 2. Advantages of scheme 由变频器完成各级张力控制,使用张力传感器实现张力控制,系统简单且稳定。用PLC或同步控制器来控制驱动辊变频器速度,同时作为其他变频器的线速度信号。 The tension sensor is used to achieve tension control, and the system is simple and stable. Use PLC or synchronous controller to control the speed of the drive roller converter, as well as the linear speed signal of other inverters. S350闭环张力控制(有感矢量控制)轻松实现加减速过程中的张力恒定,节省安装张力 S350 closed-loop tension control (inductive vector control) can easily realize the tension constant in the acceleration and deceleration process, saving the installation tension 辊的空间,降低机械成本,同时高精度控制确保了涂布效果高度均匀。 Roll space, reduce the mechanical cost, and high precision control ensures the coating effect is highly uniform. 双工位收放卷具有预驱动功能,可满足高速不停机自动换卷、提高生产效率的需求。同时准确的收卷控制可以避免菜心式不良收卷,使收卷效果更好。 The double station roll has the pre-drive function, which can meet the demand of automatic changing of the high speed and no stop, and improving the production efficiency. At the same time, the control can avoid the core type unroll, which can make the winding effect better.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|